Content for comparison

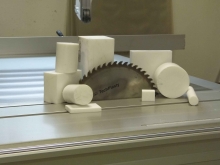

PTFE - teflon

PTFE has the lowest coefficient of all materials and is ideal in applications where lubricants are not desirable as PTFE functions without any lubricants. PTFE has the widest working temperature range of all plastics, from -260°C to 260°C. PTFE is excellent for use in cryogenic applications as shows no embrittlement. PTFE has very good sealing properties. PTFE is not flammable unless in 94% oxygen environment. PTFE is an excellent insulating material. PTFE is not ideal in high wear abrasive applications or in high loading applications. Here filled PTFE is used to improve resistance to load and wear.

- Chemical applications, sealing applications

- Insulating materials in demanding electrical applications

- Low friction applications

- Gaskets

- Bearing pads

- Chemical equipment, valve seats, valves in gas cylinders, bellows etc.

- Chemically inert to all known industrial chemicals;

- Low co-efficient of friction, non-stick & non-toxic;

- Wide temperature range (-260°C to +260 °C);

- Exhibits excellent permeation resistance;

- Excellent dielectric properties;

Group of materials Teflon:

Engineering plastics and their products can be ordered from TechPlasty. Materials in the same group from different manufacturers are not always directly interchangeable because they may not all have the same technical parameters. Our technical consultants, who have many years of experience in the field of engineering plastics, will be pleased to advise you on the differences in the individual materials, especially in the boundary conditions. Detailed technical data of individual manufacturers' materials can be found in their data sheets.