Content for comparison

PA66+GF30 - polyamide 66 glass fiber reinforced

PA66+GF30 is a 30 % glass fibre reinforced PA66. It demonstrates outstanding mechanical properties such as higher strength, rigidity, creep strength and dimensional stability. Compared to unreinforced PA66, the properties of this glass filled modification GF30 make this material suitable for use in parts that are exposed to high static loads over long periods in high temperature conditions. As glass fibres tend in some cases to have a marked abrasive effect on mating surfaces, PA66+GF30 is less suitable for sliding applications.

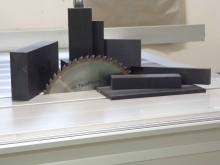

Processing of glass-filled plastics - composites.

Such composites are known for their excellent properties, but their machining is extremely difficult. However, the other benefits of these materials are worth the effort. When machining by milling, turning or just cutting, internal stress is created more than in ordinary plastics, and the stresses occur unevenly, which can have undesirable results. Composites also cause rapid tool wear. Improper machining can generate excessive heat, which leads to cracks and delamination, making the material unusable. Coolants present additional problems. Sharp tools, their correct geometry, annealing, heating before machining, etc. can help. It is always advisable to consider the processing of composites by a professional company with experience, such as TechPlasty.

- Highly loaded structural elements

- Abrasion-resistant and dimensionally stable machine components

- Pulleys

- very high stiffness

- resistant to many oils, greases and fuels

- good wear properties

- very high strength

- high dimensional stability

- good weldable and bondable

Engineering plastics and their products can be ordered from TechPlasty. Materials in the same group from different manufacturers are not always directly interchangeable because they may not all have the same technical parameters. Our technical consultants, who have many years of experience in the field of engineering plastics, will be pleased to advise you on the differences in the individual materials, especially in the boundary conditions. Detailed technical data of individual manufacturers' materials can be found in their data sheets.

Some materials trade names are protected trademarks..

Celstran® PA66-GF30 is a registered trademark of Celanese; Tecamid® 66 GF30 is a registered trademark of Ensinger; Murylon® A black+GF is a registered trademark of Murtfeldt; Sustamid® 66 GF 30 is a registered trademark of Röchling; Zellamid® 250 GF 30 is a registered trademark of Zell-Metall;

All other trademarks or registered trademarks are the property of their respective owners.